CHARGING CIRCUIT

Learning

Objective: Identify

charging-circuit components, their functions, and

maintenance procedures.

The charging system performs

several functions, which are as follows:

· It recharges the

battery after engine cranking or after the use of electrical accessories with

the engine turned off.

· It supplies all

the electricity for the vehicle when the engine is running.

· It must change

output to meet different electrical loads.

· It provides a

voltage output that is slightly higher than battery voltage.

charging circuit.

A

TYPICAL CHARGING CIRCUIT CONSISTS OF THE FOLLOWING:

BATTERY- provides current to

energize or excite the alternator and assists in

stabilizing initial alternator

output.

ALTERNATOR or GENERATOR- uses

mechanical (engine) power to produce

electricity.

ALTERNATOR BELT- links the engine

crankshaft pulley with alternator/ generator

pulley to drive the alternator/

generator.

VOLTAGE REGULATOR- ammeter,

voltmeter, or warning light to inform the

operator of charging system condition.

ALTERNATORS

The alternator has replaced the dc generator because of its

improved

efficiency. It is smaller,

lighter, and more dependable than the dc generator. The

alternator also produces more

output during idle which makes it ideal for late model

vehicles.

The alternator has a spinning magnetic field. The output windings (stator) are

stationary. As the

magnetic field rotates, it induces current in the output windings.

Alternator

Construction

Knowledge of the construction of

an alternator is required before you can understand

the proper operation, testing

procedures, and repair procedures applicable to an

alternator.

The primary components of an

alternator are as follows:

ROTOR ASSEMBLY (rotor shaft, slip

rings, claw poles, and field windings)

STATOR ASSEMBLY (three stator

windings or coils, output wires, and stator core)

RECTIFIER ASSEMBLY (heat sink,

diodes, diode plate, and electrical terminals)

ROTOR ASSEMBLY (fig. 2-22).- The

rotor consists of field windings (wire wound

into a coil placed over an iron

core) mounted on the rotor shaft. Two claw-shaped pole

pieces surround the field windings to increase the

magnetic field

STATOR

ASSEMBLY

(fig. 2-24).- The stator

produces the electrical output of the

alternator. The stator,

which is part of the alternator frame when assembled, consists of

three

groups of windings or coils which produce three separate ac currents. This is

known as three-phase output. One end of the windings is connected

to the stator

assembly and the other is

connected to a rectifier assembly. The windings are wrapped

around a soft laminated iron core

that concentrates and strengthen the magnetic field

around the stator windings. There

are two types of stators-

· Y -type stator

and

· Delta type stator.

Figure

Figure 2-24.- Stator assembly.

The Y-type stator (fig. 2-25) has the wire

ends from the stator windings connected to a

neutral junction. The

circuit looks like the letter Y. The Y-type stator provides good

current output at low

engine speeds.

Figure 2-25.- Electrical diagram indicating a Y-type stator

The delta-type stator (fig. 2-26) has the stator

wires connected end-to-end. With no

neutral junction, two

circuit paths are formed between the diodes. A delta-type stator is

used in high output alternators.

Figure 2-26.- Electrical diagram indicating a

delta-type stator.

RECTIFIER

ASSEMBLY.

The

rectifier assembly, also known as a diode assembly, consists of six diodes used to

convert stator ac output into dc current. The current flowing from the winding is

allowed

to pass through an insulated diode. As

the current reverses direction, it flows

to ground through a grounded diode. The insulated and grounded diodes prevent the

reversal

of current from the rest of the charging system. By this switching action and

the

number of pulses created by motion between the windings of the stator and

rotor, a

fairly

even flow of current is supplied to the battery terminal of the alternator.

The

rectifier diodes are mounted in a heat sink (metal mount for removing excess

heat

from

electronic parts) or diode bridge. Three positive diodes are press-fit in an

insulated

frame. Three negative diodes are mounted into an uninsulated or grounded

frame.

When an alternator is producing

current, the insulated diodes pass only outflowing

current to the battery. The

diodes provide a block, preventing reverse current flow

from the alternator. Figure 2-27

shows the flow of current from the stator to the

battery.

A cross-sectional view of a

typical diode is shown in figure 2-28. Note that the figure

also shows the diode symbol used

in wiring diagrams. The arrow in this

symbol

Indicates

the only direction that current will flow. The diode is sealed to keep moisture

out.

Alternator

Operation

The operation of an alternator is

somewhat different than the dc generator. An

alternator has a rotating magnet

(rotor) which causes the magnetic lines of force to

rotate with it. These lines of

force are cut by the stationary (stator) windings in the

alternator frame, as the rotor

turns with the magnet rotating the N and S poles to keep

changing positions. When S is up

and N is down, current flows in one direction, but

when N is up and S is down,

current flows in the opposite direction. This is called

alternating current as it changes

direction twice for each complete revolution. If the

rotor speed were increased to 60

revolutions per second, it would produce 60-cycle

alternating current.

Figure

Figure 2-27.- Current flow from the stator to the

battery.

ALTERNATOR

OUTPUT CONTROL

A voltage regulator controls

alternator output by changing the amount of current flow

through the rotor windings. Any

change in rotor winding current changes the strength

of the magnetic field acting on

the stator windings. In this way, the voltage regulator

can maintain a preset charging

voltage.

The

three basic types of voltage regulators are

as

follows:

1. Contact

point voltage regulator, mounted away from the alternator in the engine compartment

2. Electronic voltage regulator, mounted away from the alternator in the engine compartment

3.

Electronic voltage regulator, mounted on the back or inside the alternator

The contact point voltage

regulator uses a coil, set of points, and resistors that limits

system voltage. The electronic or

solid-state regulators have replaced this older type.

For operation, refer to the "Regulation of

Generator Output" section of this chapter.

The electronic voltage

regulators use an electronic circuit to control rotor field strength

and

alternator output. It is a sealed unit and is not repairable. The electronic

circuit

must

be sealed to prevent damage from moisture, excessive heat, and vibration. A

rubber

like gel surrounds the circuit for protection.

An

integral voltage regulator is mounted inside or on the rear of the alternator.

This is

the

most common type used on modern vehicles. It is small, efficient, dependable,

and

composed

of integrated circuits.

An

electronic voltage regulator performs the same operation as a contact point

regulator,

except that it uses transistors, diodes, resistors, and capacitors to regulate

voltage

in the system. To increase alternator output, the electronic voltage regulator

allows

more current into the rotor windings, thereby strengthen the magnetic field

around

the rotor. More current is then induced into the stator windings and out of the

alternator.

To reduce alternator output, the electronic regulator

increases the resistance between

the battery and the rotor windings. The magnetic field

decreases and less current is

induced into the stator windings.

Alternator speed and

load determines whether the regulator increases or decreases

charging output. If

the load is high or rotor speed is low (engine at idle), the regulator

senses a drop in

system voltage. The regulator then increases the rotors magnetic field

current until a

preset output voltage is obtained. If the load drops or rotor speed

increases, the

opposite occurs.

Alternator

Maintenance

Alternator testing

and service call for special precautions since the alternator output

terminal is connected

to the battery at all times. Use care to avoid reversing polarity

when performing

battery service of any kind. A surge of current in the opposite

direction could bum the

alternator diodes.

· Do

not purposely or accidentally "short" or "ground" the

system when disconnecting wires or connecting test leads to terminals of the

alternator or regulator. For example, grounding of the field terminal at either

alternator or regulator will damage the regulator. Grounding of the alternator

output terminal will damage the alternator and possibly other portions of the

charging system.

· Never

operate an alternator on an open circuit. With no battery or electrical load in

the circuit, alternators are capable of building high voltage (50 to over 110

volts) which may damage diodes and endanger anyone who touches the alternator

output terminal.

Alternator maintenance is minimized by the use of pre

lubricated bearings and longer

lasting

brushes. If a problem exists in the charging circuit, check for a

complete field

circuit by placing a

large screwdriver on the alternator rear-bearing surface. If the field

circuit is complete,

there will be a strong magnetic pull on the blade of the

screwdriver, which

indicates that the field is energized. If there is no field current, the

alternator will not

charge because it is excited by battery voltage.

Should you suspect

troubles within the charging system after checking the wiring

connections and

battery, connect a voltmeter across the battery terminals. If the

voltage reading, with

the engine speed increased, is within the manufacturer's

recommended

specification, the charging system is functioning properly. Should the

alternator tests

fail, the alternator should be removed for repairs or replacement. Do

NOT forget, you must

ALWAYS disconnect the cables from the battery first.

ALTERNATOR

TESTING

To determine what

component( s) has caused the problem, you will be required to

disassemble and test

the alternator.

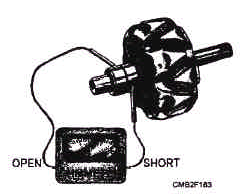

ROTOR

TESTING.- To test the rotor for grounds, shorts, and opens, perform the

following:

To check for grounds,

connect a test lamp or ohmmeter from one of the slip rings to

the rotor shaft (fig.

2-29). A low ohmmeter reading or the lighting of the test lamp

indicates that the rotor winding is

grounded.

Figure 2-29.- Testing rotor for grounds.

To check the rotor

for shorts and opens, connect the ohmmeter to both slip rings, as

shown in figure 2-30.

An ohmmeter reading below the manufacturer's specified

resistance value

indicates a short. A reading above the specified resistance value

indicates an open. If

a test lamp does not light when connected to both slip rings, the

winding is open.

Figure 2-30.- Testing the rotor for opens and

shorts.

STATOR

TESTING.- The stator winding can be tested for opens and grounds after it

has been disconnected

from the alternator end frame.

If the ohmmeter

reading is low or the test lamp lights when connected between each

pair of stator leads

(fig. 2-31), the stator winding is electrically good.

A high ohmmeter

reading or failure of the test lamp to light when connected from any

one of the leads to

the stator frame (fig. 2-32) indicates the windings are not grounded.

It is not practical

to test the stator for shorts due to the very low resistance of the

Winding

Figure 2-32.- Testing a stator

for grounds.

DIODE

TESTING.- With the stator windings disconnected, each diode may be tested

with an ohmmeter or

with a test light. To perform the test with an ohmmeter, proceed

as follows:

Connect one ohmmeter

test lead to the diode lead and the other to the diode case (fig.

2-33). Note the

reading. Then reverse the ohmmeters leads to the diode and again note

the reading. If both

readings are very low or very high, the diode is defective. A good

diode will give one

low and one high reading.

An alternate method

of testing each diode is to use a test lamp with a 12-volt battery.

To perform a test

with a test lamp, proceed as follows:

Connect one of the

test leads to the diode lead and the other test lead as shown in

figure 2-34. Then

reverse the lead connections. If the lamp lights in both checks, the

diode is defective.

Or, if the lamp fails to light in either direction, the diode is

defective. When a

good diode is being tested, the lamp will light in only one of the two

checks

\

Figure 2-34.- Testing diodes with a test lamp.

CHARGING

SYSTEM TEST

Charging system tests

should be performed when problems point to low alternator

voltage and current.

These tests will quickly determine the operating condition of the

charging system.

Common charging system tests are as follows:

Charging system

output test-measures current and voltage output of the charging

system.

Regulator voltage

test- measures charging system voltage under low output, low load

conditions.

Regulator bypass

test- connects full battery voltage to the alternator field, leaving the

regulator out of the

circuit.

Circuit resistance

tests- measures resistance in insulted and grounded circuits of the

charging system.

Charging system tests

are performed in two ways- by using a load tester or by using a

volt-ohm-millimeter

(VOM/ multimeter). The load tester provides the accurate method

for testing a

charging system by measuring both system current and voltage.

Charging

System Output Test

The charging system

output test measures system voltage and current under maximum

load. To check output

with a load tester, connect tester leads as described by the

manufacturer, as you

may have either an inductive (clip-on) amp pickup type or a no inductive

type tester. Testing

procedures for an inductive type tester are as follows:

With the load tester

controls set as prescribed by the manufacturer, turn the ignition

switch to the RUN

position. Note the ammeter reading.

Start the engine and

adjust the idle speed to test specifications (approximately 200

rpm).

Adjust the load

control on the tester until the ammeter reads specified current output.

Do not let voltage

drop below specifications (about 12 volts). Note the ammeter

reading.

Rotate the control

knob to the OFF position. Evaluate the readings.

To calculate charging

system output, add the two ammeter readings. This will give you

total charging system

output in amps. Compare this figure to the specifications within

the manufacturer's

manual.

Current output

specifications will depend on the size (rating) of the alternator. A

vehicle with few

electrical accessories may have an alternator rated at 35 amps,

whereas a larger

vehicle with more electrical requirements could have an alternator

rated from 40 to 80

amps. Always check the manufacturer's service manual for exact

values.

If the charging

system output current tested low, perform a regulator voltage test and a

regulator bypass test

to determine whether the alternator, regulator, or circuit wiring is

at fault.

Regulator

Voltage Test

A regulator voltage

test checks the calibration of the voltage regulator and detects a

low or high setting.

Most voltage regulators are designed to operate between 13.5 to

14.5 volt range. This

range is stated for normal temperatures with the battery fully'

charged. Regulator

voltage test procedure is as follows:

Set the load tester

selector to the correct position using the manufacturer's manual.

With the load control

OFF, run the engine at 2,000 rpm or specified test speed. Note

the voltmeter reading

and compare it to the manufacturer's specifications.

If the voltmeter

reading is steady and within manufacturer's specifications, then the

regulator setting is

okay. However, if the volt reading is steady but too high or too low,

then the regulator

needs adjustment or replacement. If the reading were not steady, this

would indicate a bad

wiring connection, an alternator problem, or a defective

regulator, and

further testing is required.

Regulator

Bypass Test

A regulator bypass

test is an easy and quick way of determining if the alternator,

regulator, or circuit

is faulty. Procedures for the regulator bypass test is similar to the

charging system

output test, except that the regulator be taken out of the circuit. Direct

battery voltage

(unregulated voltage) is used to excite the rotor field. This should allow

the alternator to

produce maximum voltage output.

Depending upon the

system there are several ways to bypass the voltage regulator. The

most common ways are

as follows:

Sorting a test tab to

ground on the rear of the alternator (if equipped).

Placing a jumper wire

across the battery and field terminals of the alternator.

With a remote

regulator, unplug the wire from the regulator and place a jumper wire

across the battery

and field terminals in the wires to the alternator.

CAUTION

Follow the

manufacturer's directions to avoid damaging the circuit. You must NOT

Short or connect

voltage to the wrong wires or the diodes or voltage regulator may be

Ruined.

When the regulator

bypass test is being performed, charging voltage and current

INCREASE to normal

levels. This indicates a bad regulator. If the charging voltage

And current REMAINS

THE SAME, then you have a bad alternator.

CIRCUIT

RESISTANCE TEST

A circuit resistance

test is used to locate faulty wiring, loose connections, partially

Burnt wire, corroded

terminals, or other similar types of problems.

There are two common

circuit resistance tests- insulated resistance test and ground

Circuit resistance

test.

INSULATED

RESISTANCE TEST

To perform an

insulated resistance test, connect the load tester as described by the

Manufacturer. A

typical connection setup is shown in figure 2-35. Note how the

Voltmeter is

connected across the alternator output terminal and positive battery

Terminal.

With the vehicle

running at a fast idle, rotate the load control knob to obtain a 20-amp

Current flow at 15

volts or less. All accessories and lights are to be turned OFF. Read

the voltmeter. The

voltmeter should NOT read over 0.7-volt drop (0.1 volt per

Electrical

connection) for the circuit to be considered in good condition. However, if

The voltage drop is

over 0.7 volt, circuit resistance is high and a poor electrical Connection

exists.

GROUND

CIRCUIT RESISTANCE TEST

With the ground

circuit resistance test the voltmeter leads are placed across the

Negative battery

terminal and alternator housing (fig. 2-36).

The voltmeter should

NOT read over 0.1 volt per electrical connection. If the reading

is higher, this

indicates such problems as loose or faulty connections, burnt plug

Sockets, or other similar malfunctions

6.6.2 Charge balance calculation

The charge balance or energy

balance of a charging system is used to ensure that the alternator can cope

with all the demands placed on it and still charge the battery. The following

steps help to indicate the size of alternator required or to check if the one

fitted to a vehicle is suitable.

As a worked example, the figures

from Table 6.1

will be used. The calculations

relate to a passenger car with a 12 V electrical system. A number of steps are

involved.

1. Add the power used by all the

continuous and prolonged loads.

2. Total continuous and prolonged

power (P1) _440W.

3. Calculate the current at 14 V

(I = W/V) _ 31.5

A.

4. Determine the intermittent

power (factored by 0.1) (P2) _ 170W.

5. Total power (P1 +P2) =610W.

6. Total current =610/14

= 44

A.

Electrical component

manufacturers provide tables to recommend the required alternator, calculated

from the total power demand and the battery size. However, as a guide for 12 V

passenger cars, the rated output should be about 1.5 times the total current

demand (in this example 44 _ 1.5 _ 66

A).

Manufacturers produce machines of

standard sizes, which in this case would probably mean an alternator rated at

70 A. In the case of vehicles with larger batteries and starters, such as for

diesel-powered engines and commercial vehicles, a larger output alternator may

be required. The final check is to ensure that the alternator output at idle is

large enough to supply all continuous and prolonged loads (P1) and still

charge the battery. Again the factor of 1.5 can be applied. In this example the

alternator should be able to supply (31.5 _ 1.5) _ 47

A, at engine idle. On normal systems this relates to an alternator speed of

about 2000 rev/min (or less). This can be checked against the characteristic

curve of the alternator.

No comments:

Post a Comment